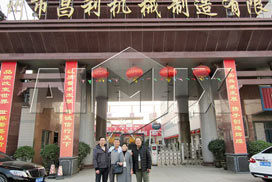

ALQ120 Stationary Asphalt Mixing Plant Was Finished Installation In Malaysia

ALQ120 Stationary Asphalt Mixing Plant Was Finished Installation In Malaysia Project Overview Location: Malaysia Plant Name: Asphalt Plant Model: ALQ120 stationary type … Read more…

Learn More