Productivity: 25m³/h-360m³/h

Hot Sale in UAE, Saudi Arabia, Qatar, Oman, Iraq

High Quality, High Temperature Resistance

Suitable for commercial concrete production,civilian building construction fields.

Different Types of Concrete Batching Plant

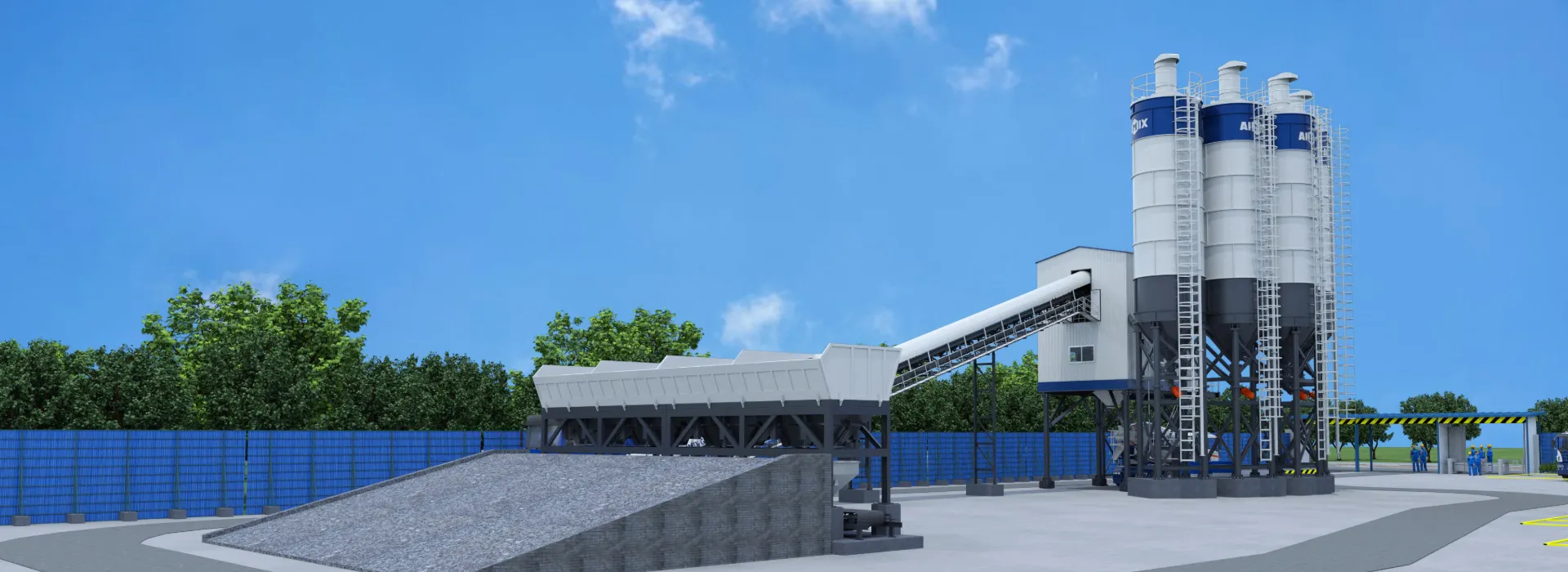

Concrete batch plants, or mixing plants, combine components to produce concrete. AIMIX offers stationary, mobile, small/mini, and drum-type plants to meet the needs of large, medium and small concrete production projects. The choice depends on concrete volume, project specs, and available space and resources.

Stationary Concrete Batching Plant

Hot Models: AJ60AJ90AJ120AJ180AJ240AJ360

Productivity : 60-360 m³/h

Mixer: Twin shaft mixer, Planetary

Aggregate Feeder: belt type or hopper type

Application Fields: Large concrete production project, commercial concrete production

Get A Quote >

Mobile Concrete Batching Plant

Hot Models: AJY35AJY50AJY60AJY90

Productivity : 35-90 m³/h

Mixer: Twin shaft mixer, Planetary

Aggregate Feeder: belt type or hopper type

Application Fields: Small and medium-sized Civilian building construction and precast concrete production projects, and the site needs to be changed frequently.

Get A Quote >

On-site Mobile Concrete Batching Plant

Hot Models: AJSY25AJSY35

Productivity : 25-35m³/h

Mixer: twin shaft mixer

Aggregate Feeder: 2×3.5 m³

Application Fields: Concrete production projects with limited space, civilian building construction, precast concrete production

Get A Quote >

Drum-type Concrete Batching Plant

Hot Models: AJT35AJT50AJT60

Productivity : 35-60 m³/h

Mixer: JZM750-JZM1500

Mixing Period: 90-120 s

Application Fields: Small-scale civilian building construction

Get A Quote >

Main Configuration

Storing System

- Bolted or welded

- Horizontal or vertical

- Storage capacity: 30T to 800T

Mixing System

- Twin shaft mixer

- Sicoma concrete mixer

- Planetary type

Aggregate Batching System

- Capacity: 560L- 4800L

- Bins: 2bins, 3bins, 4bins, etc

- Automatic batching

Control System

- Power panel and switches

- Collective control terminals

- Automatic control unit

Application Fields

Civilian Building Construction

AJ and AJY concrete batching plants provide stable and high-quality concrete for residential and public buildings, ensuring the strength and durability of the structures.

Commercial Concrete Production

AIMIX AJ series stationary plants are employed for large-scale commercial concrete production, meeting the market demand for various construction projects, and ensuring standardized and efficient supply of concrete.

Precast Concrete Production

AJ and AJY concrete batching plants support the production of precast concrete elements such as panels, beams, and columns, offering precise concrete mixes that enhance production efficiency and product quality.

Global Projects

AJ40 Concrete Batching Plant – Residential housing construction

- Project Time: February 20, 2025

- Mixing Capacity: 40m³/h

- Mixer: twin shaft mixer

- Mixer Discharging Volume (L): 1000

- Aggregate Material Quantity (m3): 20×3

- Cement Silo (t) (optional): 1×100

- Application Field: Residential housing construction. The customer purchased a stone crushing plant from AIMIX to produce aggregates for concrete mixing. The produced concrete was used for the construction of its own residential project. The overall cost was much lower than purchasing aggregates from an aggregate plant.

Get A Quote >

AJ180 Concrete Batching Plant In Kazakhstan

- Mixing Capacity: 180m³/h

- Mixer: twin shaft mixer

- Mixer Discharging Volume (L): 3000

- Feeding Volume (L): 4800

- Aggregate Material Quantity (m3): 20×4

- Cement Silo (t) (optional): 4×100

- Application Field: For Commercial Concrete Production

Get A Quote >

AJ60 Concrete Batching Plant In Indonesia

- Mixing Capacity: 60m³/h

- Mixer: twin shaft mixer, planetary

- Mixer Discharging Volume (L): 1000

- Feeding Volume (L): 1600

- Aggregate Material Quantity (m3): 80/60

- Cement Silo (t) (optional): 2×100

- Application Field: For Road Construction

Get A Quote >

AJ90 Concrete Batching Plant In Armenia

- Mixing Capacity: 90m³/h

- Mixer: twin shaft mixer, planetary

- Mixer Discharging Volume (L): 1500

- Feeding Volume (L): 2400

- Aggregate Material Quantity (m3): 15×4

- Cement Silo (t) (optional): 3×100

- Application Field: For Commercial Concrete Production

Get A Quote >

AJSY35 Concrete Batching Plant In Malaysia

- Mixing Capacity: 35m³/h

- Mixer: JS750

- Feeding Way: Belt type

- Delivery Time: Mar, 2024

- Application Field: For road construction use.

Get A Quote >

AIMIX Service

Original parts supply

Original parts supply