Types of Concrete Batching Plant

Concrete batching plants, or mixing plants, combine components to produce concrete. AIMIX offers stationary, mobile, on-site mobile type plants to meet the needs of large, medium and small concrete production projects. The choice depends on concrete volume, project specs, and available space and resources.

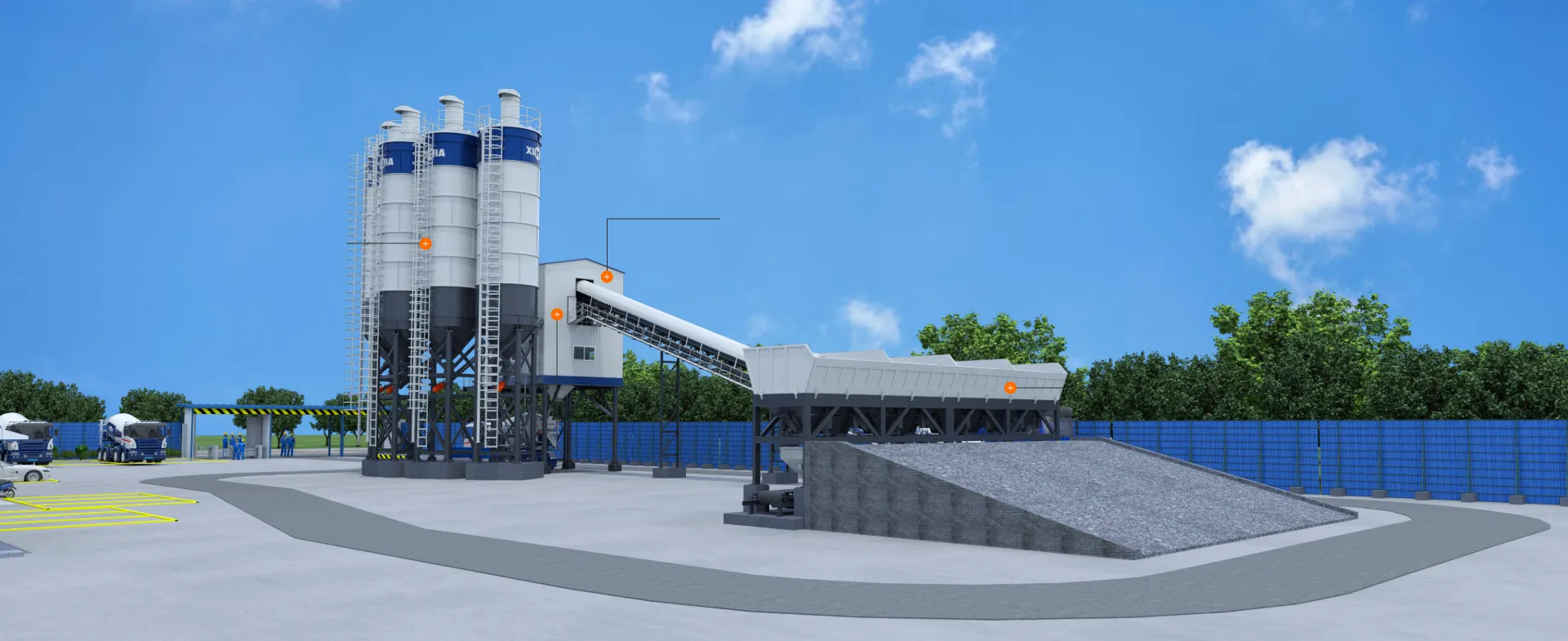

Stationary Concrete Batching Plant

Production Capacity: 60-360m³/h

Fully Automated Operating System; IoT Remote-Control System

Two/Three/Four Bins Batching Machine

Mixer: Twin shaft mixer, Planetary

Application: Commercial concrete production, Residential housing construction,

Precast concrete production, and other construction fields.

Get A Quote

AJY Mobile Batching Plant

Production Capacity: 60-120m³/h

Movement Mode: Semi-trailer

Easy to disassemble, high mobility, convenient and fast, strong site adaptability.

Suitable for concrete production projects with limited construction sites.

Get A Quote

AJSY On-site Mobile Batching Plant

Production Capacity: 20m³/h, 40m³/h

Max. Aggregate Size: 80/60 mm

Equipped with JS Twist Shaft Mixer

Features:

1. Mixing System: Structural upgrade → 30% increased

mixing capacity;

2. Control System: Industry-first intelligent wireless remote

operation → Reduces crew to just 1 operator;

3. Batching System:

<1% weighing error (vs. industry-standard 2%);

Simultaneous weighing & mixing → Continuous production

Get A Quote

Hot Sale Models Of Concrete Batching Plant

Productivity: 60m³/h

Mixer: Twin shaft mixer, Planetary

Mixer Discharging Volume (L): 1000

Aggregate Feeder: belt type or hopper type

Feeding Volume (L): 1600

Application: Mainly used in the medium-sized road construction, residential building construction, concrete precast construction, etc.

Production Capacity: 90 m³/h

Mixer: twin shaft mixer, planetary

Mixer Discharging Volume (L): 1500

Feeding Volume (L): 2400

Application fields: Medium and large-sized civil building construction projects, precast concrete production and commercial concrete production.

Production Capacity: 120 m³/h

Mixer: twin shaft mixer, planetary

Mixer Discharging Volume (L): 2000

Feeding Volume (L): 3200

Fields of Application: Large concrete production projects, construction of civil buildings, production of precast concrete elements.

Production Capacity: 180 m³/h

Mixer: twin shaft mixer, planetary

Mixer Discharging Volume (L): 3000

Feeding Volume (L): 4800

Application: Large-scale concrete production project, such as commercial concrete production, concrete precast production, road and building construction project.

Main Configuration

Storing System

- Bolted or welded

- Horizontal or vertical

- Storage capacity: 30T to 800T

Mixing System

- Twin shaft mixer

- Sicoma concrete mixer

- Planetary type

Aggregate Batching System

- Capacity: 560L- 4800L

- Bins: 2bins, 3bins, 4bins, etc

- Automatic batching

Control System

- Power panel and switches

- Collective control terminals

- Automatic control unit

Concrete Production Solutions

| Application Fields |

|

|

| Production Capacity | 90m³/h, 120m³/h, 180m³/h, 240m³/h, 360m³/h | 25m³/h, 35m³/h, 60m³/h, 75m³/h, 90m³/h |

| Model | AJ-90, AJ-120, AJ-180, AJ-240, AJ360 | AJ-25, AJ-35, AJ-50, AJ-75, AJ-90 |

| Applications | Suitable for large construction projects and infrastructure development:

|

Suitable for precast concrete production:

|

| Features | Continuous batch production, direct supply to construction sites, and quick response to orders are required. | Factory-based, standardized components (beams, pipes, panels). |

Global Projects

AJ90 Batching Plant Powers Ecuador’s New Concrete Supplier

- Mixing Capacity: 90m³/h

- Opeartion Time: Jan 2026

- Application Field: Self-supply for road construction projects and entry into commercial concrete supply market

- Customer Background: First-time batching plant investor in Ecuador

- Challenges & Concerns: Client had never operated or maintained batching equipment and need complete training and support system.

- How AIMIX Responded: AIMIX technical team physically present throughout installation; Comprehensive Training Program; Regular follow-up consultations.

From First Plant to Market Leader: Why a Kazakh Supplier Chose AIMIX AJ180 Again

- Mixing Capacity: 180m³/h(twin shaft mixer)

- Mixer Discharging Volume (L): 3000

- Customer’s Background: A Kazakh concrete supplier partnered with AIMIX for the second time to strengthen their leadership in the local market.

- Challenges & Concerns: Kazakhstan’s ongoing infrastructure boom. To capture more market share, the customer needed to significantly increase his production capacity—and fast.

- How AIMIX Responded: AIMIX delivered customized layout solutions tailored to the client’s site needs, enabling accelerated production, on-time delivery, and seamless operational integration.

Get A Quote >

AIMIX AJ50 Helps Mexican Builder Launch Ready-Mix Business

- Mixing Capacity: 50m³/h(twin shaft mixer)

- Mixer Discharging Volume (L): 1500

- Customer’s Background: A Mexican construction and precast supplier entered the concrete production industry

- Challenges & Concerns: 1. Service Anxiety: The client worried about after-sales support;

2. Delivery Pressure: Tight project timelines required fast shipment and installation - How AIMIX Responded: 1. Clearly explained the service process, remote support system, and local partner network;

2. Streamlined production and logistics to deliver the plant within the client’s deadline

Get A Quote >

Winning Through Quality: How AIMIX AJ60 Batching Plant Secured Mining Client in Laos

- Mixing Capacity: 60m³/h(twin shaft mixer)

- Customer’s Background: A Lao mining firm launched a competitive bid to replace its aging concrete plant—a critical upgrade for its expanding operations.

- Challenges & Concerns: As a major capital investment, the client needed assurance of product quality, technical support, and long-term partnership value.

- How AIMIX Won Trust: 1. Proven Quality – AIMIX invited the customer to visit our factory;

2. Custom Solutions – Customized plans for specific needs;

3. Long-term Partnership – Emphasized ongoing support beyond just equipment.

Get A Quote >

AJ180 Concrete Batching Plant In Kazakhstan

- Mixing Capacity: 180m³/h

- Mixer: twin shaft mixer

- Mixer Discharging Volume (L): 3000

- Feeding Volume (L): 4800

- Aggregate Material Quantity (m3): 20×4

- Cement Silo (t) (optional): 4×100

- Application Field: For Commercial Concrete Production

Get A Quote >

How to Choose a Suitable Concrete Batching Plant?

Here are some concerns a customer may have when considering purchasing a concrete batching plant:

| Items | AJSY mini mobile batching plant | AJ stationary concrete batching plant | AJY mobile concrete batching plant | AJZY drum type concrete plant |

|---|---|---|---|---|

| Concrete mixing capacity | 35/50 m3/h | 25-240 m3/h | 25-120 m3/h | 15-60 m3/h |

| Final concrete quality | high | high | high | middle |

| Foundation requirements | free foundation | concrete foundation | simple concrete foundation | free foundation |

| Installation period | 0.5 day | 7-10 day | 3-7 days | 1-2 days |

| Required land area | low | high | high | low |

| Mobile flexibility | high | low | middle | middle |

| Control system | Manual/Fully automatic control | Fully automatic control | Fully automatic control | Semi Auto with Control Panel |

To make it easier for you to understand the differences among Aimix concrete batching plants, we made this form.

You can choose the ideal type of concrete batching plant for your needs.

If there are any other factors you are concerned about concrete batching plant, please contact us and we will provide customized service to you.

AIMIX Service

Original Parts Supply

Original Parts Supply